Σειρά C ΓΩΝΙΑΚΑ ΦΙΛΤΡΑ

ΓΕΩΡΓΙΑ

Γωνιακά Φίλτρα Σειρά C

ΕΦΑΡΜΟΓΕΣ: Πρόληψη της σκωρίας στις γραμμές αναρρόφησης και τις αντλίες.

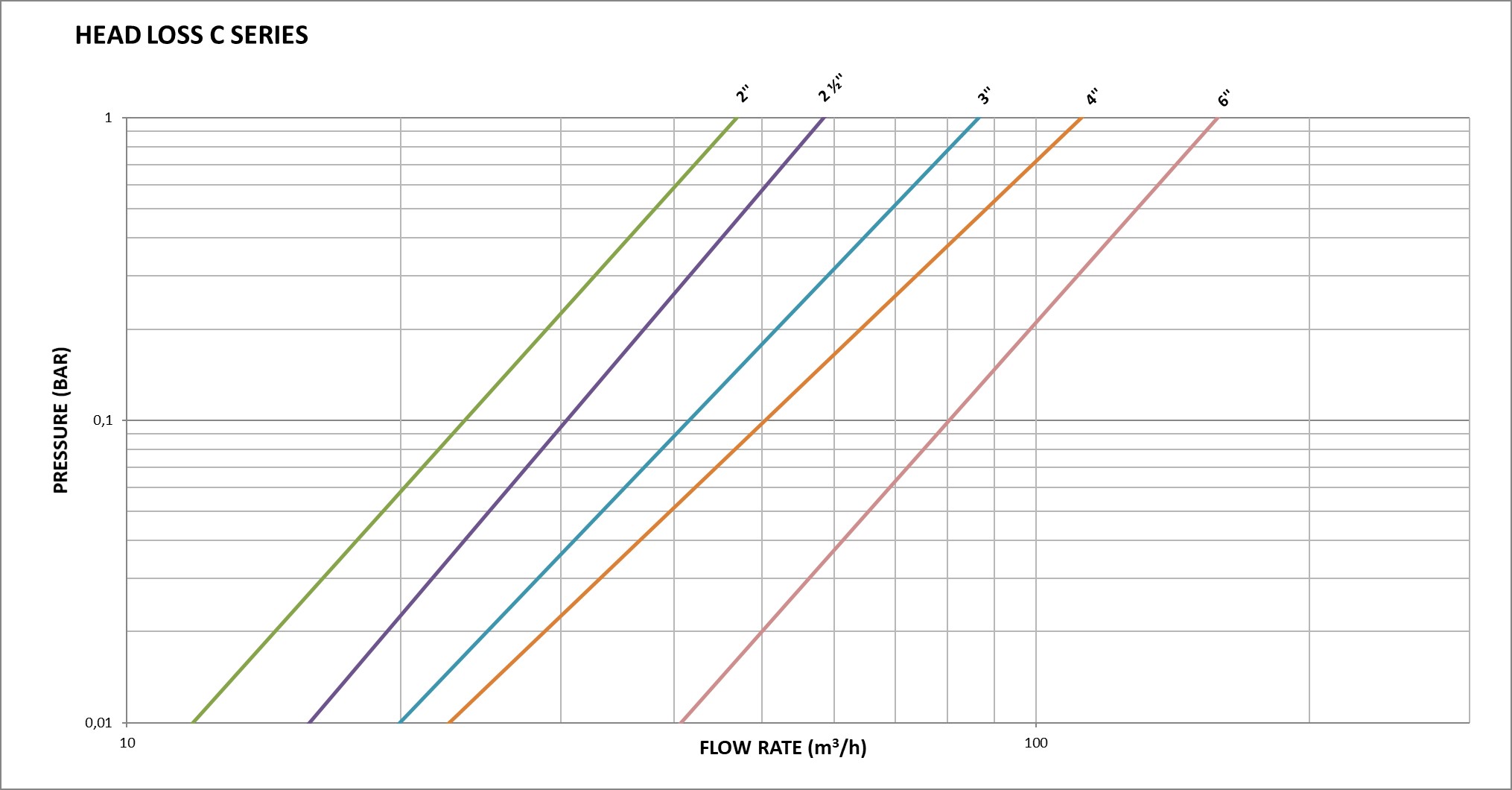

ΧΡΗΣΗ: Τα φίλτρα σίτας της σειράς C χρησιμοποιούνται για φιλτράρισμα νερού με χαμηλή συγκέντρωση ανόργανων αιωρούμενων στερεών (π.χ. άμμος). Επίσης, μπορεί να χρησιμοποιηθεί ως δευτερεύον φίλτρο μετά από συστήματα πρωτογενούς φιλτραρίσματος (π.χ. φίλτρο μέσων, υδροκυκλώνες κ.λπ.). Διατίθενται επίσης με δύο στοιχεία σίτας για φιλτράρισμα 2 σταδίων.

ΕΓΚΑΤΑΣΤΑΣΗ: Η εγκατάσταση του φίλτρου γίνεται ακολουθώντας την κατεύθυνση του βέλους ροής στο σώμα του φίλτρου. Το νερό εισέρχεται στην είσοδο, διέρχεται από το εσωτερικό στοιχείο, φιλτράρεται και εξέρχεται από την έξοδο. Η γωνία μεταξύ εισόδου-εξόδου είναι 90⁰.

ΣΥΝΤΗΡΗΣΗ: Το φίλτρο καθαρίζεται χειροκίνητα, αποσυναρμολογώντας το καπάκι και αφαιρώντας το εσωτερικό στοιχείο της σίτας. Ο καθαρισμός πρέπει πάντα να γίνεται όταν η διαφορά πίεσης εισόδου-εξόδου είναι 0,5 bar μεγαλύτερη από τη διαφορά πίεσης ενώ το στοιχείο της σίτας είναι καθαρό.

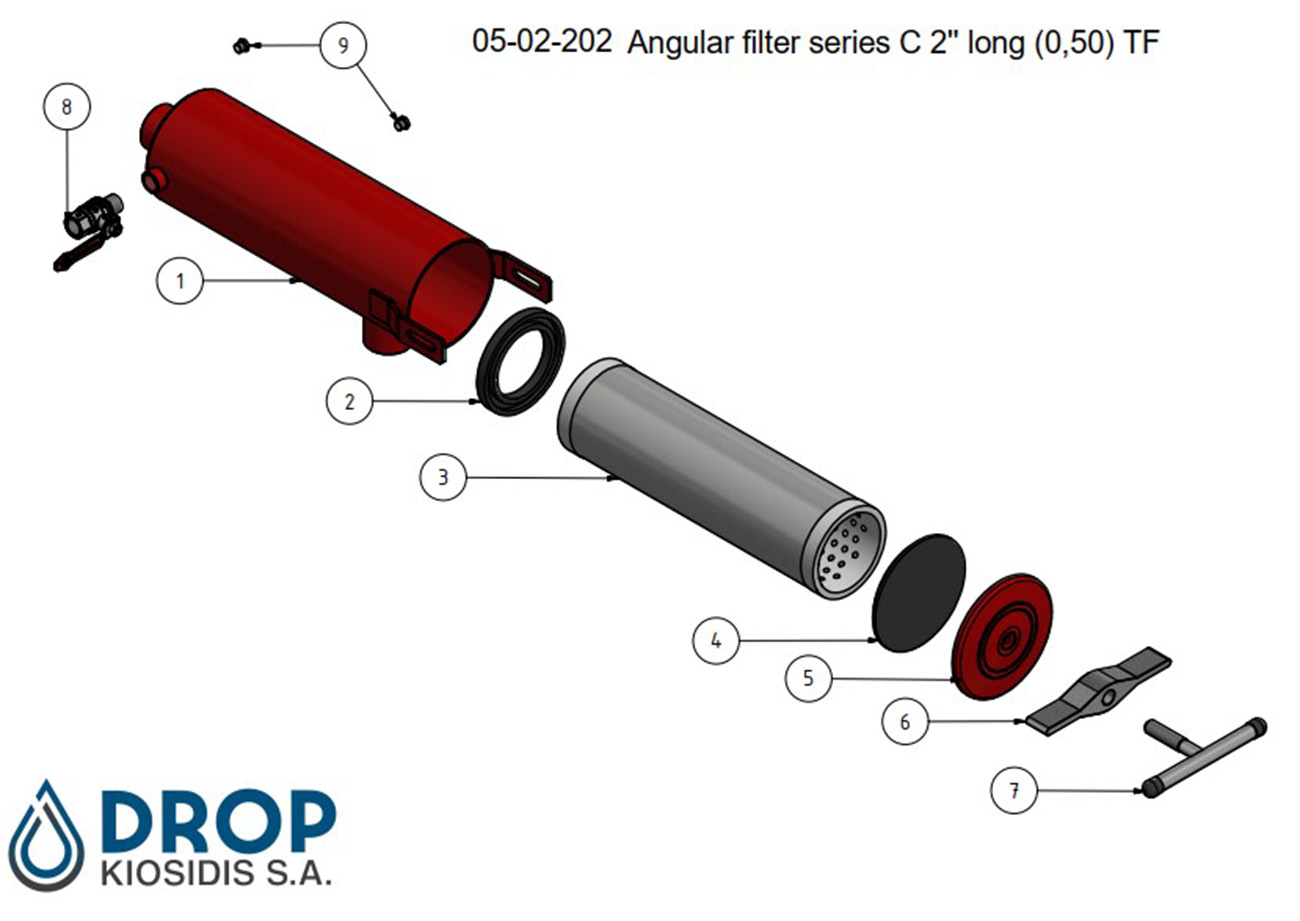

Υλικά

ΣΩΜΑ: Χάλυβας S235JR (διατίθεται επίσης σε ανοξείδωτο AISI 304 & 316, κατόπιν αιτήματος)

ΣΤΟΙΧΕΙΟ ΣΙΤΑΣ: u-PVC (DIN8061-8062)/ σίτα από ανοξείδωτο χάλυβα (AISI 304)/ διάτρητη ανοξείδωτη λαμαρίνα (για μοντέλα μεγαλύτερα από 6 ")

ΕΛΑΣΤΟΜΕΡΗ: EPDM

ΕΠΙΦΑΝΕΙΑΚΗ ΕΠΕΞΕΡΓΑΣΙΑ: Χημικός καθαρισμός (φωσφάτωση, αποξείδωση) και ηλεκτροστατική βαφή με πούδρα πολυεστέρα (διαθέσιμες επικαλύψεις κατάλληλες για πόσιμο νερό)

ΔΙΑΘΕΣΙΜΑ ΜΕΓΕΘΗ ΣΙΤΑΣ: 60 mesh/ 250μm, 80 mesh/ 180 μm, 120 mesh/ 125μm, 140 mesh/ 106 μm, 170 mesh/ 90 μm, άλλα μεγέθη κατόπιν αιτήματος

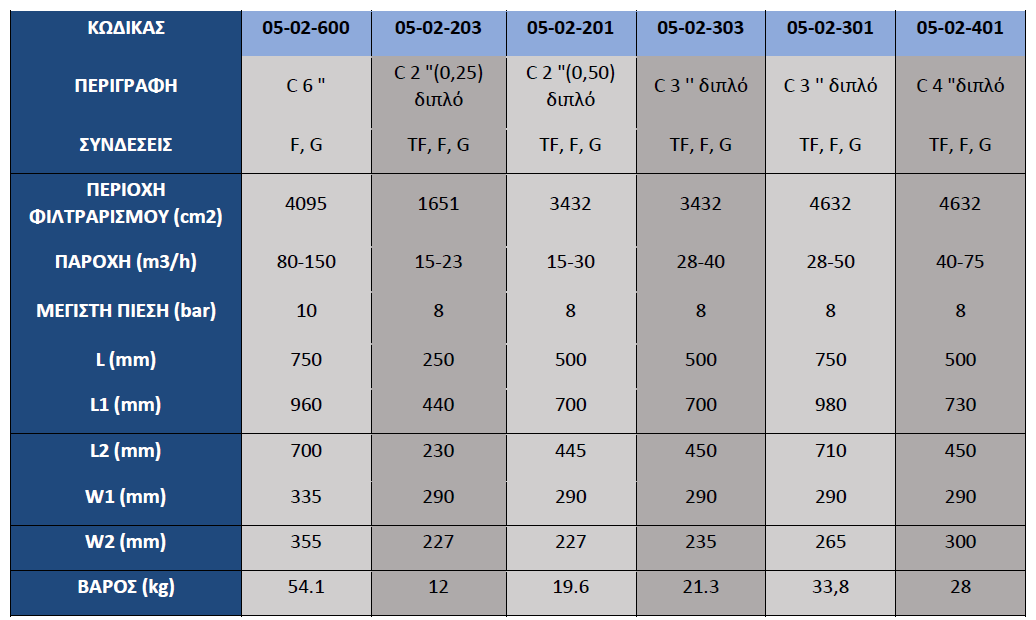

Part list

Part list 05-02-200

Part list 05-02-201

Part list 05-02-202

Part list 05-02-203

Part list 05-02-250

Part list 05-02-300

Part list 05-02-301

Part list 05-02-303

Part list 05-02-400

Part list 05-02-401

Part list 05-02-403

Part list 05-02-600